Work complete: Overhaul, Draught Proofing, Reglazes and Splice Repairs (Replacing rotten timber.)

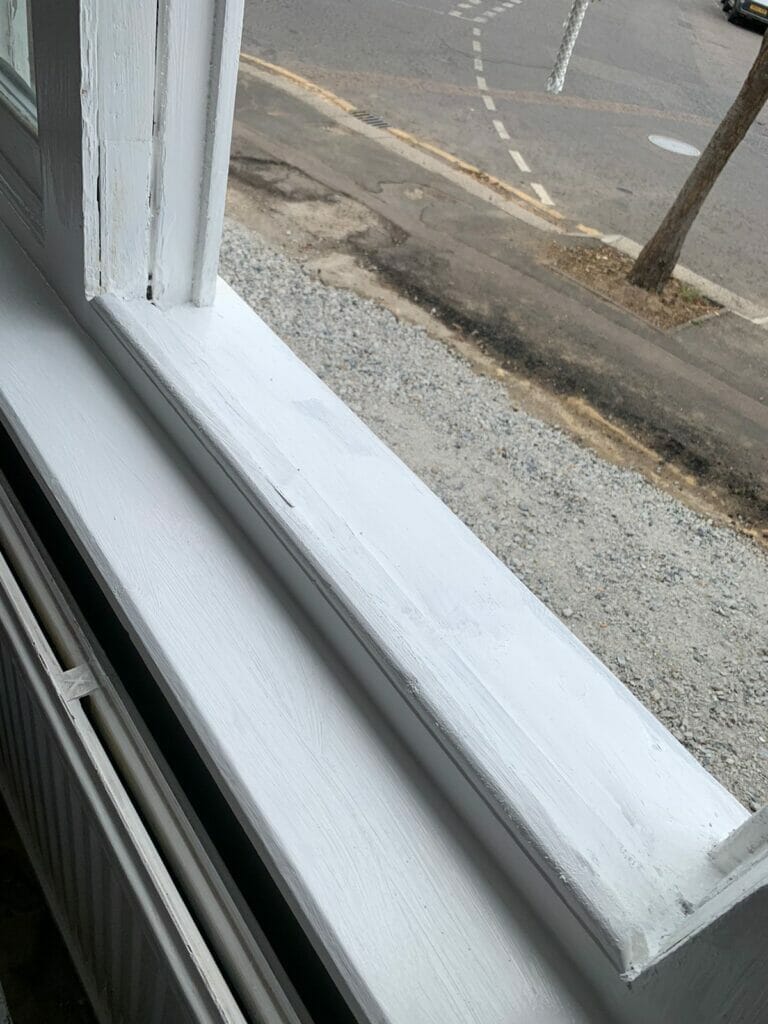

Today the team completed the repairs, overhaul, and draught proofing on our customers original wooden sash windows. We offered a cost-effective way for the customer to prolong the life of our customers original sash windows over more expensive replacements. As you can see from the pictures there was a considerable amount of rot and damage to the frames. Replacing the timber like for like (softwood for softwood and hardwood for hardwood) the team carried out splice repairs on both the box frames and sashes. All rot was cut out and the areas treated with wood rot treatment prior to new timber being installed. All repairs were filled, sanded, and primed. Replacement panes were installed in place of any cracked panes as identified during our assessment, these were removed, new pieces cut and puttied on site.

When removing and reinstalling sash windows to carry out repairs it is not uncommon for us to recommend draught proofing the windows at the same time. The main reasons are the windows are already out making it far easier to install a draught proofing system at the same time. Furthermore, it is actually more cost effective due to the current VAT rate being 0% for draught proofing. This means that many of the elements we need to carry out to ensure that the draught proofing is working properly will be inclusive of the 0% VAT. However, we are always happy to offer both options to our customers to make their own decision.

The draught proofing of the sash windows is carried out by routeing 8mm grooves into the top of the top sash (top rail,) meeting rail of the bottom sash (where top and bottom sash meet) and the bottom of the bottom sash (bottom rail.) This allows us to install a flat runner (u-section) for a brush (brush pile) to be slid in. This means over many years of catching external dirt and dust the brush can lose its efficiency but can be easily slid out and replaced. We also replace the parting bead with a new bead which is preloaded with a brush. The new parting bead is installed resting against the top sash (facing externally) and cut at the meeting rail (so the joint is not visible.) Then it is installed against the bottom sash (facing internally.) Lastly, we install draught proofing into the staff beads (replaced if necessary) which is reinstalled to ensure a good seal. The use of brush rather than foam is to avoid sticking or tearing of the draught proofing material which is common when working with old sash windows. The brush pile has a plastic fin which helps block out the draughts and assists with noise reduction.